I had a couple of friends over to play with deconstructed screen printing last weekend. While I had once made a screen print with white school glue I had not, done deconstructed screen printing before. Oh what fun. The possibilities are endless. Deconstructed screen printing is a technique of screen printing where you make a design on the screen using thickened dyes. (We added MX dyes to sodium alginate.) You let those dyes dry on the screen. Then you pull either clear alginate (no dye added), or the thickened dyes across the screen to print it. Sometimes the dried dyes act as a resist, and you print the open area of the screen. However, after a short time the dried dyes start to break down and print as well. It is pretty cool. I have pictures to show you...

Ok, here is my first screen (to right). I used a paint brush to paint this simple design. The black was very clumping and didn't spread even. I wanted to leave the visible brush strokes in the red to see how they would print out. Here is how they printed.

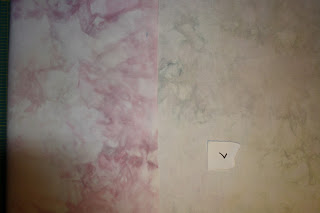

Print #1 (below, left), I used the clear alginate so the original colors would show. I had to let the alginate sit on the screen for a while to release the dried dyes.

Print #2 (below, right) didn't come out quite as nice as the first. Again I used the clear alginate, but just pulled it across the screen twice and didn't let it sit on the screen.

Ok, here is my first screen (to right). I used a paint brush to paint this simple design. The black was very clumping and didn't spread even. I wanted to leave the visible brush strokes in the red to see how they would print out. Here is how they printed.

Print #1 (below, left), I used the clear alginate so the original colors would show. I had to let the alginate sit on the screen for a while to release the dried dyes.

Print #2 (below, right) didn't come out quite as nice as the first. Again I used the clear alginate, but just pulled it across the screen twice and didn't let it sit on the screen.

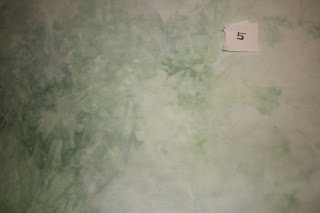

Print # 3 (below, left), I used a green thickened dye. You can see where there is still dye dried to the screen.

In print #4 (above, right) I pulled yellow through the screen. Being new to this, I stopped after this print and washed the screen. After doing the second screen, I think I could have still gotten more prints out of this screen. Too bad I washed! Below is screen #2 followed by the prints that I made from it. I made this screen by laying cut fruit and vegetables down on the table and then pulling green and blue dye over them. Where the fruit and vegetables touched the screen, the dye was resisted and left open space (mostly). I put green on one side of the screen and blue on the other. I did like the effect of the color difference on the prints.

Here is the screen as the

thickened dye is drying.

You can see the green pepper

clearly. There are oranges,

mushrooms, apples and

kale there also.

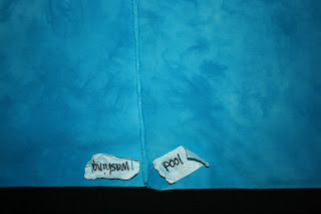

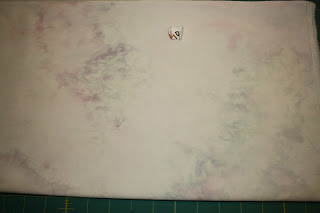

Below are the last set of prints that I got from the screen. The different colored sides shows through no matter whether I use clear or colored alginate. The last few screens I used a clear alginate. It was cool how residual colors from prior prints come out in these prints.

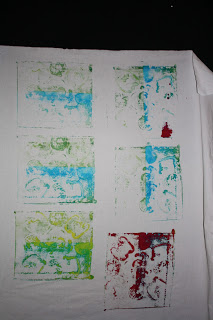

And below are the first prints from the screen... I used clear alginate for most of them. Obvouisly I used red in the one... and dropped a glob. The one in the bottom left corner, I used yellow. The yellow one show a bit more detail then the others.

Below are the middle set of prints from screen #2. After using the red, I switched back to the clear alginate. However there was some residual red that shows through the next several prints.

Here a couple close-ups of the prints from screen #2:

I did have left over thickened dyes and clear alginate and made up two more screens, so I might have more to show you at another time! Thanks for letting me share my work.

RSS Feed

RSS Feed